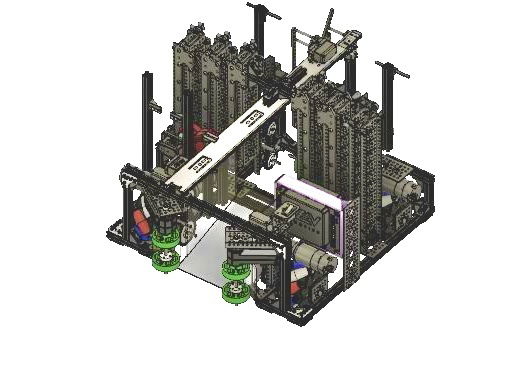

12302's Robot

Our state model of our robot is quite complex. As a team we have spent countless hours working on this robot to perfect it and prepare for the state tournament. Listed below we have everything that our robot is capable of.

Fun Facts:

Our robot (When fully extended) is taller than our shortest member at an outstanding 4'10".

This model of our robot was built in under 2 weeks.

Rumors have said that this model can dunk a basketball... this is unconfirmed but highly likely.

Our robot sucks in blocks better than most vacuums suck in dirt.

Our robot's favorite color is razzmatazz.

Most NASA engineers would say that our robot is revolutionary, we just haven't asked them yet.

Our robot can speak 54 different languages, although it prefers the language of "Beep-Boop".

Finally, our robot has discovered the 4th dimension, we just can't get it to tell us how to travel there yet.

Chassis:

We constructed our chassis in a "U" shape with our wheels sitting very low to the ground. We did this so that we have as much free space as possible on top of the robot and to keep our center of mass as low as possible.

We drive at a 13.7:1 gear ratio within the motors making us extremely fast. We use GoBilda mecanum wheels to drive in any direction that we wish while maintaining full control at all times.

Lift:

We have built a 6 stage cascade lift powered in both directions (Up and Down). With this lift we can stack up to 12 blocks but with the time allowed in the game we score 8-9 consistently. We use 100 lb fishing line to string our lift attached to a spool and motor stationed at the base of the robot. We grab the block from the notch on the top and the back of the block. We then use a drawer slide to take the block out of our chassis and on to the foundation using a rotating servo mechanism to shoot the drawer slide out.

Intake:

We use REV Core Hex Motors attached to a GoBilda Torque Servo to power our intake. The servos allows for us to move our intake according to the orientation of the block. We also have the servo set at a slight angle to ensure that the block smoothly enters our robot. The servos allow us to fold the intake wheels into our robot making sure we meet the 18" restriction using all of our space efficiently. Once the block is in our control, we have another servo that pushed the block all the way to the back of our robot to ensure that we grab the block the same way every time.

Other Mechanisms: `

Measuring tape - We use a measuring tape to park in the building site without having to drive to in order to save time and leave space for our alliance partner to park. We achieve this by attaching an Andymark compliant wheel to a continuous servo that presses against the tape so that when it spins it shoots the tape out the side of our robot.

Plate arms - We have two arms located on the back of our robot that allow us to move the foundation in both autonomous and endgame. We achieve this by attaching a piece of REV extrusion to a servo with Andymark compliant wheels for grip. We designed these arms this way so that we may use our lift to hold the stone tower at the same time that we move the plate to ensure that the tower does not fall in endgame.

Sensors and Internal Measurement Unit:

We use four color sensors. Two of the sensors are placed along the left and right side of the robot and are used for autonomous. We have found that Vuforia is not as reliable as we thought so we decided to change the stone detecting to color sensors. Using these we are able to get a specific hue, value, and saturation to determine if the block is a skystone or not. The third color sensor is placed on the bottom side of the robot. This sensor is used to detect the color of the tape under each alliance bridge. This will be used during autonomous to stop the robot under the bridge. The fourth sensor is placed at the front side of the robot. This sensor is used for automatic stacking. The sensor detects if the block is in front of it and also detects the distance from the sensor to the stone. It will use this information to position itself in the center of the stone and stack it. The Internal Measurement Unit or IMU is an internal sensor in the REV Expansion Hub that returns the robot's orientation so that during Autonomous it can be aligned reliably without it messing up too much. With all the sensors, it creates a reliable autonomous and an automatized tel-op.

Autonomous:

We have an autonomous that is able to deliver two skystone blocks and then park under the bridge. This is done using a combination of motor encoders, the IMU, and color sensors. The path for autonomous uses coordinates to determine the curved path it will follow. The reason for the curved path is for predictability and speed as it takes shortcuts and does not stop its movement. The curved path algorithm looks ahead of the robot 5 inches towards the closest line segment and creates the angle the robot needs to go at which creates this curved path. Following the path, the robot may be misaligned which the IMU can fix. The motor encoders used, determines the robots position on the X and Y value as it converts the rotations to inches for each motor. The color sensors are used to determine where the skystones are instead of Vuforia as it takes longer for them to scan and may give inaccurate readings especially in different light levels. The color sensor also detects the tape in case the robot position is really misaligned creating improved reliability.

Tele-op Programming:

We have several features in our tele-op program that helps us score better during tournaments. We have two different speed options for our drive-train, we utilize a slower and faster drive speed if the occasion rises. With the click of a button our overall speed is adjusted according to our situation. We have several different mechanisms that perform a variety of tasks during the driver controlled period. The mechanisms are split between the two drivers, the main driver controls the wheels, speed of the wheels, measuring tape, and the plate grabber arms. The secondary driver controls the lift, intake, and hand extender. The hand and lift are semi-automatic with only the first block having to be manually placed on the build plate. The automatic part of the lift is made possible because of the use of motor encoders. These encoders track the rotations of the motors and converts the rotational distance to linear distance, allowing us to input specific positions for stacking. The hand is also automatic, when the lift reaches a specified height the hand will extend to place a block. We did this by using a timer system. Each time the value of the lift is changed it will reset the timer. Once the timer reaches a certain amount it will shoot out the horizontal extender. We also have a button set to lower the arm slowly and place the stone using the same timer system allowing for easy alignment. These automatic functions in driver controlled are set in place to reduce the complexity for the drivers. For example, if we have too many buttons that need to be pressed in order to control the arms this could cause confusion for the drivers when under pressure.

Have Fun and Build On! └[ ' _ ' ]┘